Trends in Harness Architecture

Release time:

2024-01-24 00:00

In order to reduce the cost of waste, the car is disassembled to find inefficiencies in many aspects. The first is to look at things from the perspective of integration, that is, how things fit together. Secondly, based on the specification to analyze things, to explore whether the design is over-specified. Finally, look at the system from the perspective of overall product complexity.

In the current architecture, there is a box (ECU) for the electric liftgate, a box for the HVAC system, etc., all connected together through some type of CAN bus. However, the trend is moving to the right as domain-based concepts are further developed.

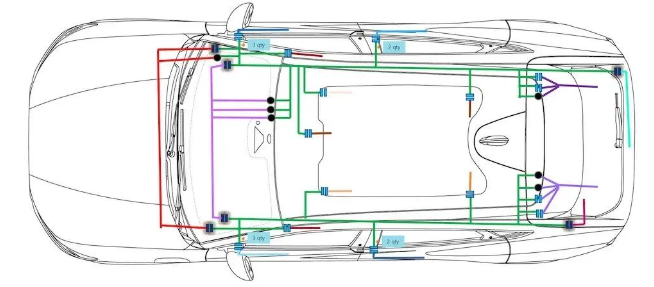

Green represents the main body harness, red represents the front or engine compartment, and magenta represents the IP harness. In the edge part, you can observe how the wiring harness is connected to the door panel, front and rear panels, A- pillar and B- pillar to the overhead, hatchback door and other components. All these different body seat belts need to be subdivided according to the way the vehicle fits on the assembly line.

This architecture forces the use of multiple interconnects (large inline connectors). The interconnect leads to additional work, additional cost, and additional potential warranty issues. Consumers get nothing. When a lamp is inserted, the consumer gets a lamp. When a module is plugged in, the client gets a processor to perform certain operations. When the connection is made due to the partition of the car, the consumer does not get any function. It enables the car to work, but does not add features or functions for consumers. It is therefore an important division between high-value and low-value costs. Whether on vehicles or agricultural equipment, it is desirable to find the greatest value with the least interconnection because they do not add value.